English

Español

Nederlands

العربية

Pусский

Deutsch

日本語

Português

Français

Italiano

한국어

ภาษาไทย

Ελληνική γλώσσα

w języku polskim

Български

eesti

dansk

suomen

česky

în limba română

slovenski jezik

svenska

magyar

हिन्दी

Türk

tiếng việt

فارسی

עברית

slovenčina

Indonesia

Lietuvių

Latviešu

Melayu

Norsk

Українськи

اردو

hrvatski

বাংলা ভাষার

తెలుగు

தமிழ்

српски језик

Wikang Tagalog

Íslensku

Català

Монгол

- HOGAR

- SOBRE NOSOTROS

- PRODUCTOS

- FÁBRICA

- SOLUCIONES

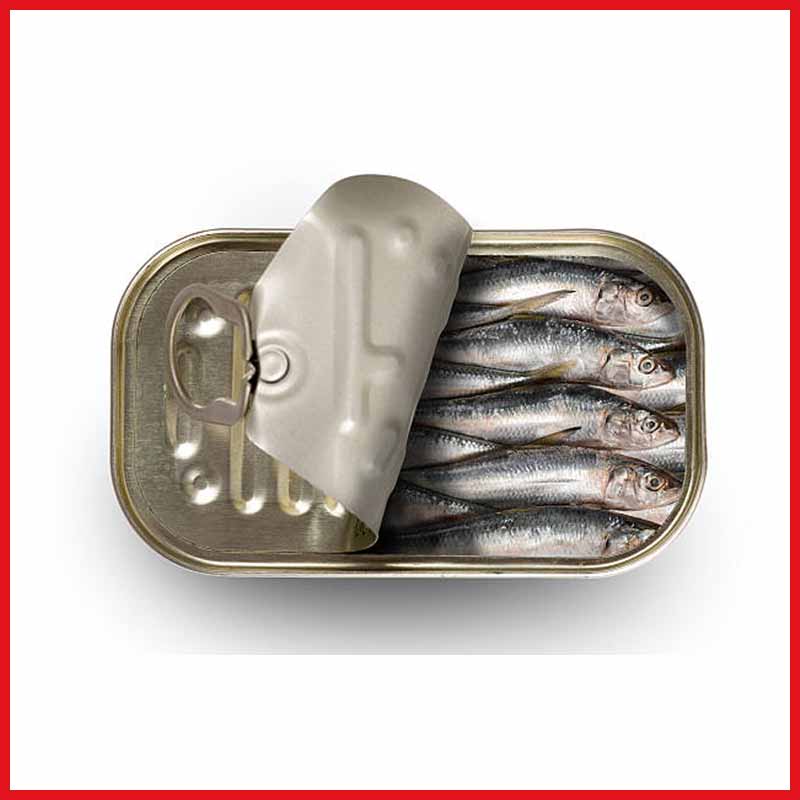

- Línea de producción de esterilización enlatada personalizada

- Línea de producción de esterilización enlatada personalizada

- Línea de producción de esterilización de bebidas con botellas de vidrio personalizadas

- Línea de producción de esterilización de bebidas con botellas de PP/HDPE personalizadas

- Línea de producción de esterilización de snacks en bolsa personalizada

- Línea de producción de esterilización de alimentos en bolsas personalizadas

- Línea de producción de esterilización enlatada personalizada

- PROYECTOS

- NOTICIAS

- Contáctenos